There’s no lack of startups around the world trying to make industrial activities more efficient with artificial intelligence. Some invent robots to assist or replace manual labor, while others use machine learning to help businesses discover insights. Synergies Intelligent Systems falls into the second category.

Michael Chang founded Synergies in 2016 in Boston to provide easy-to-use AI-powered analytics tools to medium-sized manufacturers. Having worked at Foxconn in Shenzhen in the late 2000s helping the Apple supplier improve yield rate, or reduce the percentage of defective products, using data analysis, Chang realized that not every factory has the financial profit to spend tens of thousands of dollars on digitization.

Synergies’ vision and recent growth have won investor support. The company was mostly bootstrapping during its early years, but it recently accepted venture funding to accelerate hiring, market expansion, and product development. It secured $12 million from a Series A funding round led by NGP Capital, which was formerly called Nokia Growth Partners and is backed by Nokia, as its name implies. Private equity firm New Future Capital also participated.

Synergies now operates a team of about 70 employees across Shanghai, Taipei, Guangzhou, Singapore and Boston.

The startup declined to disclose its valuation but said it’s serving nearly 100 customers, 80% of which are in Greater China, including mid-sized factories with thousands of workers run by Foxconn and Fuyao, one of the world’s largest auto glass producers. Chang told TechCrunch that Nokia and Synergies are working on some projects in the early stage, though the pair doesn’t have a large-scale partnership yet.

The Finnish telecoms titan, to Chang’s knowledge, has been promoting “industrial 5G” worldwide, which is to bring next-generation connectivity to manufacturing. So it won’t be surprising to see the two working more closely together in the future.

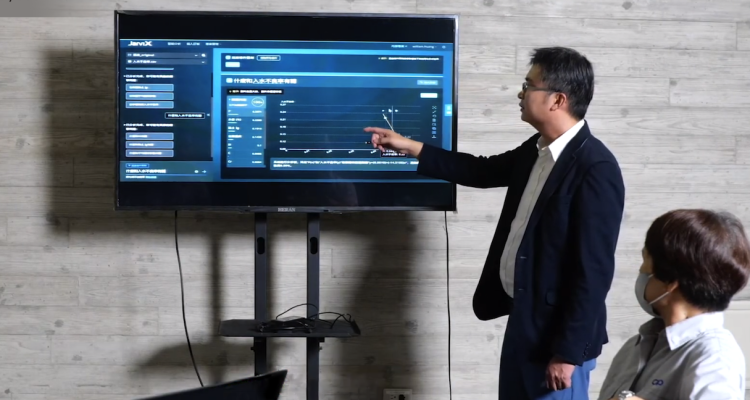

Synergies’ product could work well with 5G-powered factories that are constantly collecting and analyzing data in the cloud. It provides what’s called an “augmented analytics” platform to help manufacturers optimize efficiency on three fronts — supply chain, yield, and production capacity.

By analyzing operational data, Synergies’s software can make suggestions to managers, for example, recommending how much supply they should procure, or how to quickly change a product line to maximize capacity at the lowest cost. Once the advice is put into practice and new data is reaped, Synergies’ machine learning systems can analyze and keep refining its algorithms to help factories improve performance.

“Such machine learning isn’t rocket science for AI experts, but for an average small- and medium-sized factory in China, the overhead for creating a comprehensive ‘data middle platform’ is too high because it requires the coordination between the IT department , project managers, and AI experts,” suggested Chang, an MIT graduate with a Ph.D. in electrical engineering and computer science.

“Most small and medium factories only keep a small team of IT staff, not to mention a team of dedicated AI scientists.”

“Compared to advanced manufacturers in the West,” Chang continued. “Chinese factories, even the ones that are massive now, have only been around for four or five decades. They are a lot more price-sensitive, operate at lower margins, and want quicker returns on investment. So it’s hard to ask them to spend $10 million upfront on building a data platform.”

Using data analytics and AI to refine business decisions also addresses the problem of high turnover in the manufacturing industry, Chang explained. As population growth slows in China, factories are struggling to recruit and retain workers, meaning it’s hard to preserve workplace knowledge as well.

“It’s not a business that sees the kind of crazy growth as, say, crypto companies,” Chang maintained. “But I believe it’s a meaningful business because we are creating real changes on the ground.”